Handling bulk bags – following on from our last post.

Handling bulk bags – following on from our last post.

Handling with fork lift trucks

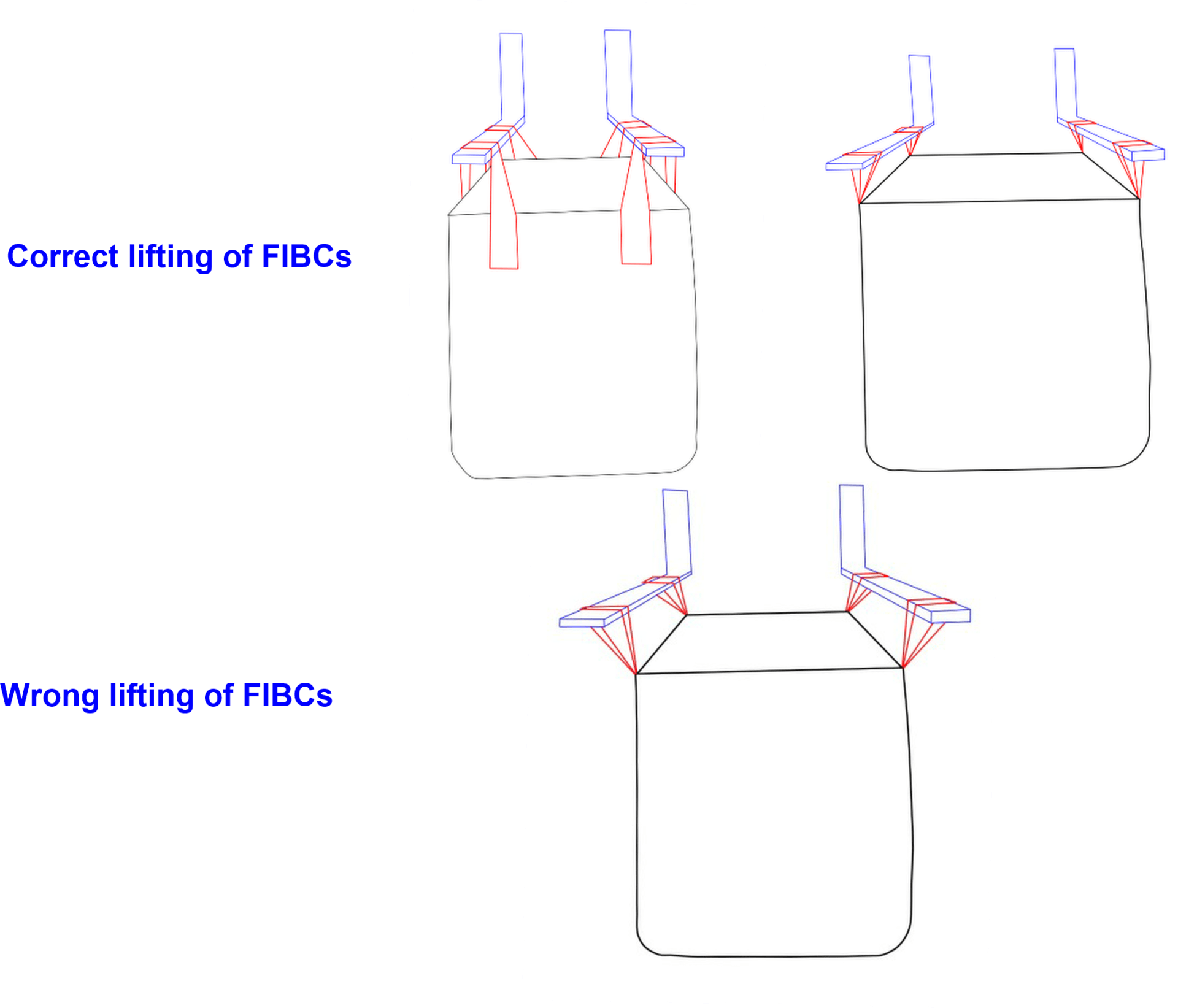

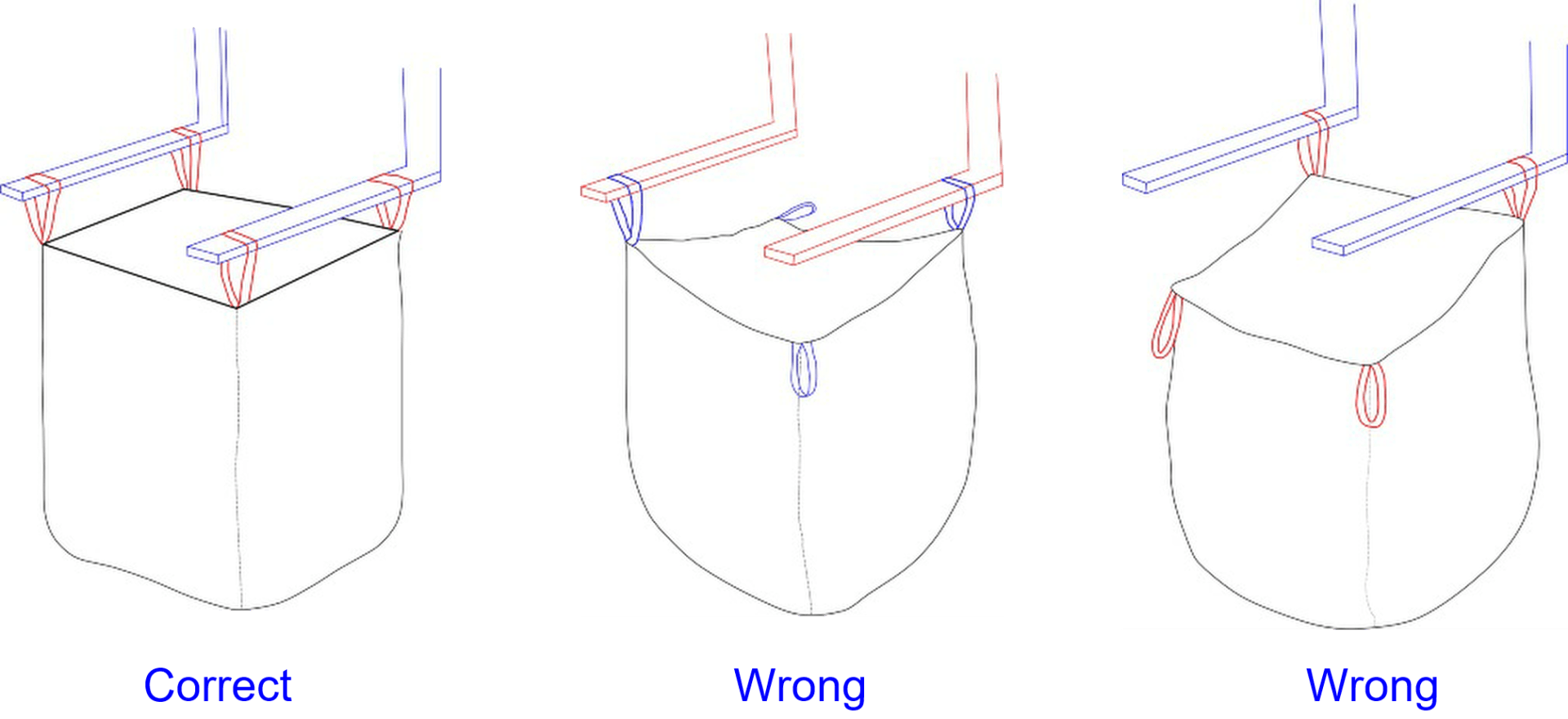

When lifting an FIBC, all four loops must be secured on the FLT tines and the folks correctly spaced to allow the loops to be directly above the side seams. There must be no twists or ‘scrunching’ on the loops when being lifted.

When handling FIBCs on a FLT, ensure that the forks are the correct length and that you can clearly see the end. This will reduce the likely hood of causing accidental damage to other stacked FIBCs.

Make operatives aware of the dangers of puncturing or damaging an FIBC can cause, by FLT or other obsticles. FIBC are a woven fabric and are not manufactured to endure aggressive treatment.

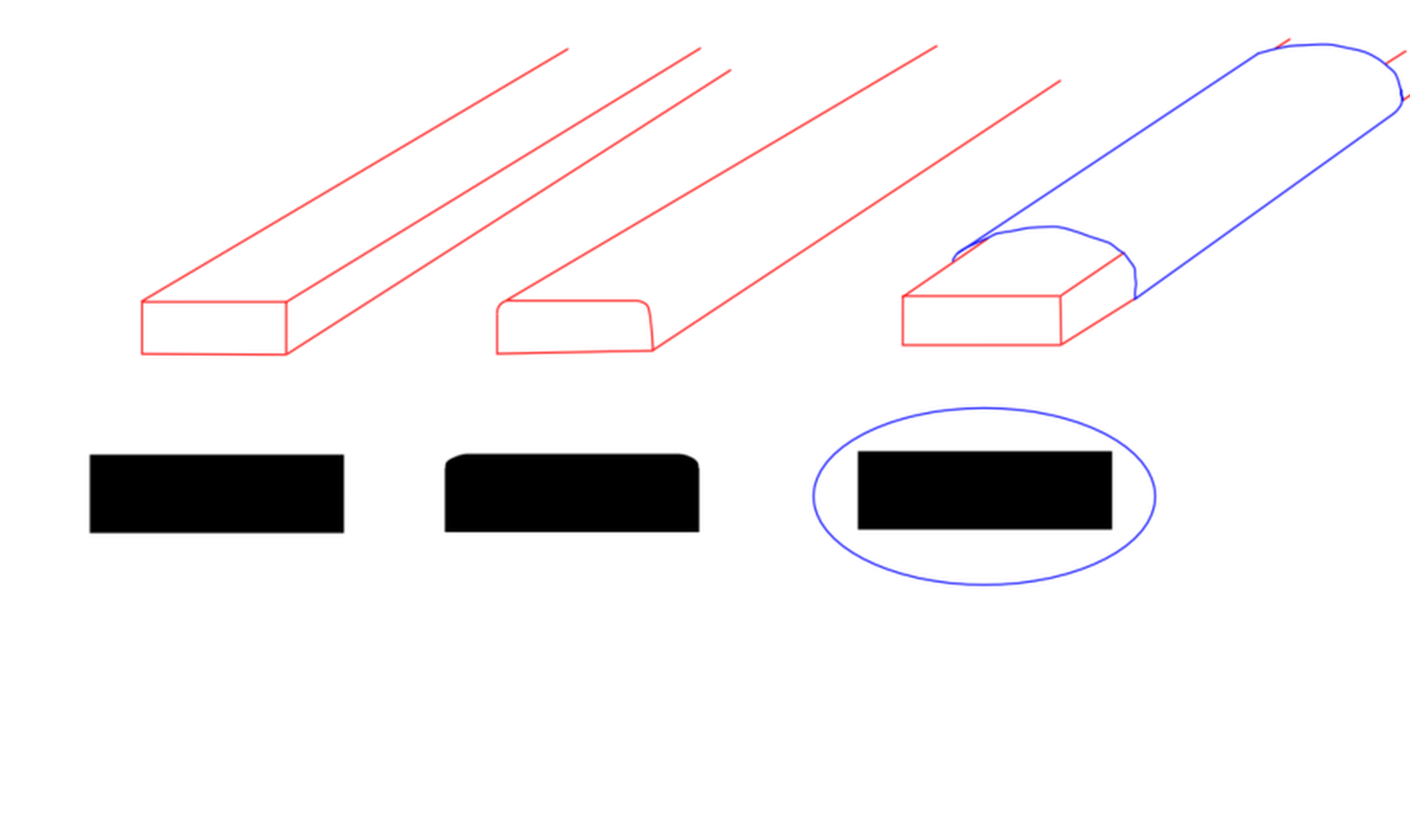

To avoid damage to the lifting loops, it is important to use rounded forks – both on top and underneath. Having sharp tines can cause abrasion or cut through the loops. Wrapping fabric around the tines/forks can help to protect the loops.

When four loops are provided on a bag, all four loops must always be used and a vertical lift should be applied. The tine width should be the same as the width of the FIBC being handled (ie 90cms x 90cms base, tines need to be approximately 90cms apart). This will enable the bag to be lifted with the loops directly above the corners, ensuring the minimum strain on side seams.

If the FIBC is on a pallet, ensure that the pallet is in good condition and that there are no obstructions for the forks. It is important to make sure the load is stable.

If a bag is not on a pallet, it must be lifted with the lifting style provided (ie 4 lifting loops, hoodlift, tunnels). A bulk bag should not be clamped, lifted by the filling or discharge spout or put onto a sling.